Product Introduction

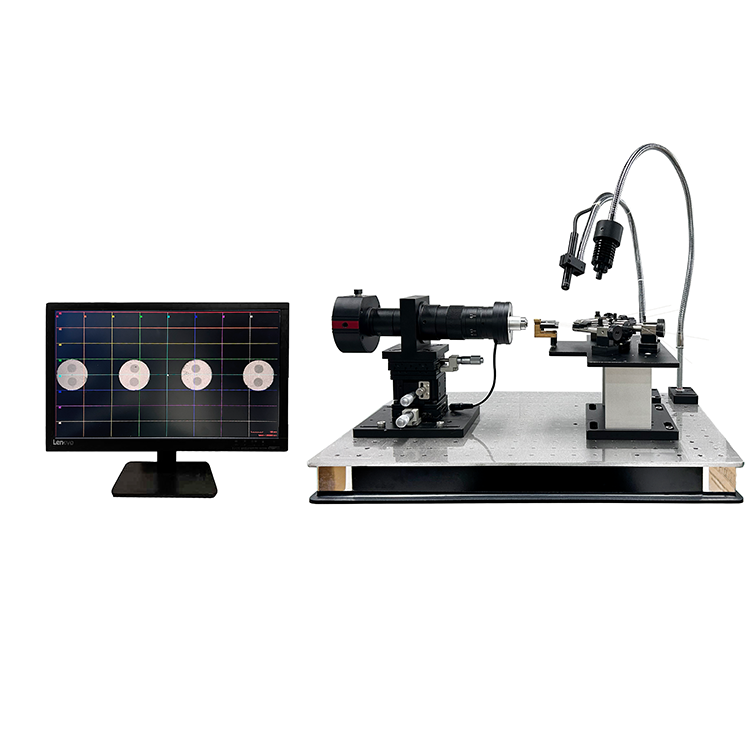

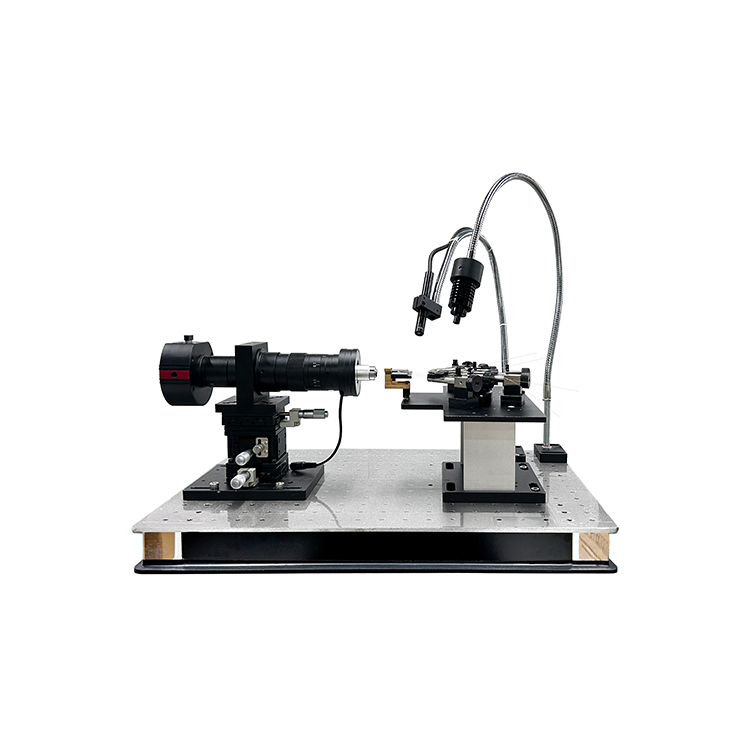

SIMINSPECTOR M50 MT/FA Polarization-maintaining fiber alignment tooling is a tool specifically designed to achieve precise alignment of MT/FA polarization-maintaining fibers.

It adopts advanced technology and precise design, which can effectively solve the axis alignment problem of MT/FA polarization-maintaining optical fibers during the connection process. Through high-precision adjustment devices and positioning systems, combined with excellent image recognition algorithms, it can ensure the precise alignment of the fiber core, effectively control the axis alignment angle to be less than ±1.5 degrees, thereby achieving high-quality optical signal transmission.

The operation of the MT/FA polarization-maintaining fiber alignment tooling is extremely simple. Equipped with an intuitive and easy-to-understand operation interface and concise control buttons, operators do not need to have profound professional knowledge and rich experience. They can quickly master its operation essentials only after simple training. The adjustment mechanism of the tooling is cleverly designed. Through simple actions such as rotation and alignment, precise alignment adjustment of MT/FA polarization-maintaining fibers can be achieved.

In the field of optical communication, the MT/FA polarization-maintaining fiber alignment tooling plays a crucial role and is one of the important tools to ensure the stable operation of optical networks.

feature

parameter

| Curing method | Heat curing or UV curing | Applicable lock cylinder | MT, mini MT ferrule, glass capillary positioning part |

| heating time | 4~6 minutes | Heating temperature | 45~120℃ adjustable |

| 对轴旋转角度 | 0~360° adjustable | Heating power | 200W、220V、50Hz |

| Imaging system | high-definition CCD | Number of axis rotators | 12 |

| screen | option | Lighting source | Built-in aperture and external point light source |

Product Configuration

| Item No. | Description | Qty |

| 1 | Optical platform | 1 |

| 2 | computer mainframe | 1 |

| 3 | computer monitor | 1 |

| 4 | Lens barrel + lens barrel light source + regulating power supply (set) | 2 |

| 5 | High-definition CCD + USB cable (set) | 2 |

| 6 | Three-dimensional adjustment frame | 1 |

| 7 | 12-axis rotating tooling | 1 |

| 8 | UV Curing Control System | 1 |

| 9 | Heating temperature control system | 1 |

| 10 | Test software | 1 |

Operation process

1. Fiber stripping, fiber core length 22-30mm;

2.Cutting optical fiber: Use an optical fiber cutter, leaving the fiber core length at 12~15mm;

3.Dispensing: Inject an appropriate amount of 353ND epoxy adhesive into the ferrule;

4.Fixed core: Fix the core on the positioning part, and mark the direction with a marker if necessary;

5.Cleaning the fiber core: Clean the front end of the optical fiber core with a cotton swab to remove dirt, ensuring that the “cat’s eye” is clearly visible.

6.Alignment axis: Rotate the aligner to place the panda eyes in the correct position, either horizontally or vertically;

7.Curing: Turn on the pre-curing switch, and initially cure the 353ND adhesive for 4-6 minutes;

8.Assembly: Assemble the ferrule into a finished connector, perform crimping, and fix the tail sleeve;

.jpg)