Product Introduction

The KL8000 series is a cost-effective fiber end-face cleaning device independently developed by our company. It can quickly and efficiently clean the end-faces of optical modules, optical components, and female fiber connectors, solving the cleaning problems of the above products. Thus, it ensures the optical characteristics of low insertion loss and high return loss during fiber coupling, and is particularly suitable for production use by manufacturers.

Working principle:

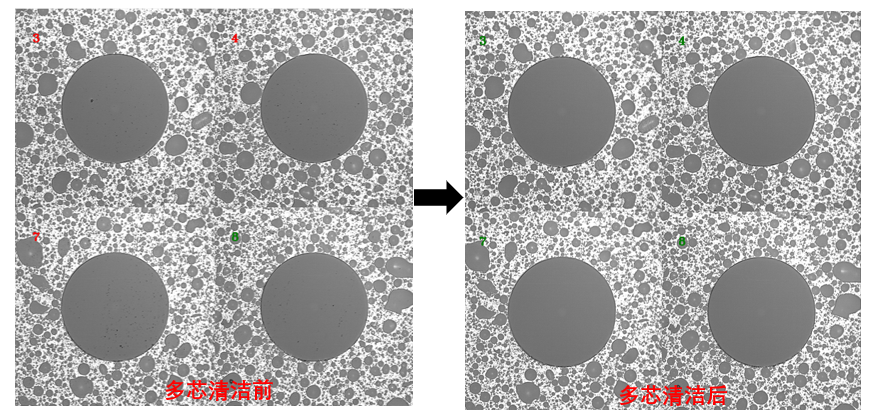

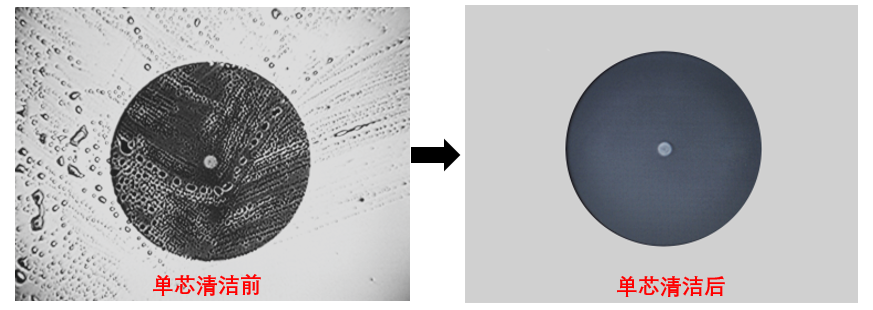

The KL8000 series fiber end-face cleaning machine adopts the cleaning principle of cleaning liquid plus gas. It uses two independent channels: an injection channel (liquid + clean gas) and an absorption channel (contaminants + exhaust gas). When the cleaning switch is pressed, first, the high-efficiency fiber end-face cleaning liquid is sprayed through the “injection channel” to quickly dissolve the oil stains and dirt on the fiber end-face. Then, dust-free gas is sprayed to blow up and float the cleaning liquid together with the oil stains and dirt. At the same time, the “absorption channel” instantly sucks away the waste gas and carries the contaminants out of the device, leaving the fiber end-face completely clean. This fundamentally solves the pollution problem and eliminates the secondary pollution of dirt in the sleeve groove.

feature

parameter

| Item | Parameter |

| Gas source | Cleaning air, N2, CO2 |

| Air pressure | 4kg~6kg |

| Power | 3W |

| Power supply | DC 24V |

| Cleaning time | 0.5s |

| Weight | 5kg |

| Size | Machine 268mm*222mm*109mm

Cleaning head φ32mm*110mm |

.jpg)